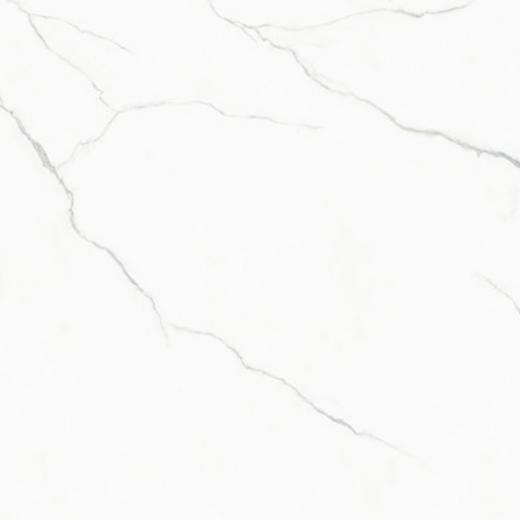

Some of our quartz slab buyers want to try sintered stone or so-called porcelain slab for their end-users. Why sintered stone can replace some quartz slabs in the construction projects? According to the relevant data, over 90% of quartz slabs are fabricated into kitchen countertop or other covering table top, because of its features on heat-resistance, anti-scratch and zero water-absorption. When porcelain slab is manufactured to enjoy these features, it becomes a choice for kitchen countertop. In comparison, quartz slabs are more like original stone material, while sintered stone looks more like ceramic tiles. And actually quartz stone is easier to cut and fabricate edges, while sintered stone is easier to happen breaking edges. So fabrication of sintered stone countertop needs more experiences and good equipment. In terms of prices, sintered stone is much cheaper than quartz stone, especially in color range of calacatta designs. Therefore, sintered stone is more acceptable for common families. Moreover, a good percentages of sintered stone is used to cover the wall with 12mm thickness, which helps realize clean and luxurious interior living spaces.

Specifications:

Size: 3200*1600*12mm;

Surface: Matt; Polished

Package: A-frame steel package or sea-worthy wood bundles;

Application: Kitchen appliances and home panel; Interior wall and floor; Bathroom space; Custom furnishing; Door panels; Stairs; Furnitures; Exterior wall;

Features:

1. Great amount of in-stock slabs with various colors and sizes for fast shipment;

2. Advanced manufacturing equipment and half-automated production line;

3. Mature management teams and clean working space;

4. Easy to match quartz slabs in full container;

5. Custom slab size and thickness;

6. Small MOQ for each color;

7. Competitive prices;

8. Free samples;

Photos: