Engineered quartz stone and sintered stone are both currently popular artificial stone materials for kitchen countertops. They both well imitate the beauty and elegance of natural stone materials, with obvious features of resistance to heat, scratch and water absorption. However, in terms of manufacturing raw materials, engineered quartz stone use about 7%-9% of resin to combines various sizes of original quartz sand and powder together, so as to form the quartz slab. While sintered stone containers no resin. With no resin additives, sintered stone is made under high heat, which feels and behaves more like brittle porcelain when it receives a sharp blow. So sintered stone is heat proof. BUT quartz stone will darken or scorch if subjected to temperatures over 150°F. Each stone material has its pros and cons, and it depends on personal needs to choose what you want.

Specifications:

Size: 3200*1600*12mm;

Surface: Rough Matt;

Package: A-frame steel package or sea-worthy wood bundles;

Application: Kitchen appliances and home panel; Interior wall and floor; Bathroom space; Custom furnishing; Door panels; Stairs; Furnitures; Exterior wall;

Features:

1. Great amount of in-stock slabs with various colors and sizes for fast shipment;

2. Advanced manufacturing equipment and half-automated production line;

3. Mature management teams and clean working space;

4. Easy to match quartz slabs in full container;

5. Custom slab size and thickness;

6. Small MOQ for each color;

7. Competitive prices;

8. Free samples;

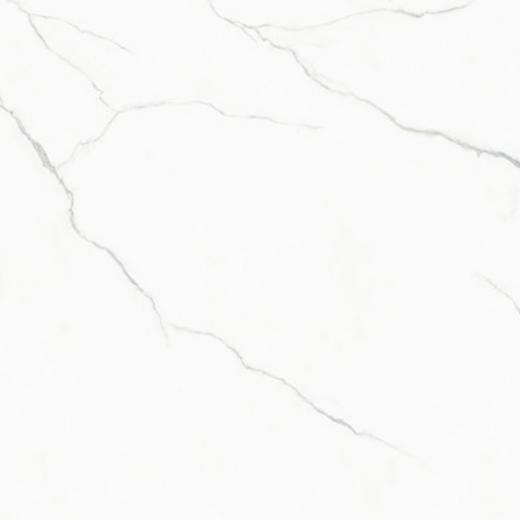

Photos: